Newsham Engine circa 1730

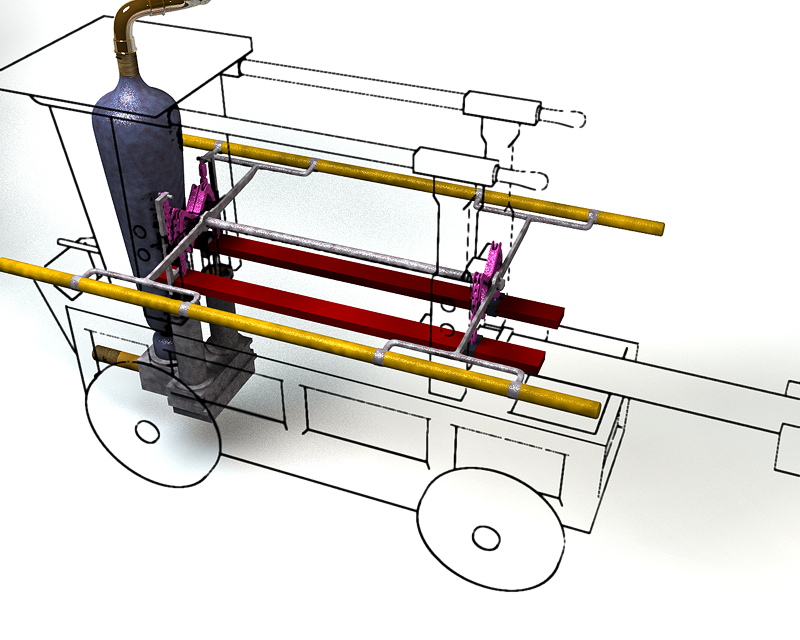

Fig #2: This x-ray view of the engine has its major components color-enhanced for clarity.

The two pump handles are yellow. They are connected by metal-colored brackets to a metal-colored center shaft. Three or four firemen on one side of the engine would pull down on the handles, which would rotate the shaft. Then the several men on the other side would pull down on the handles and rotate the shaft in the opposite direction.

The two treadles are red. Two or three men could stand on these boards shifting their weight from one foot to another. This movement would be transmitted at both ends to a "bow-tie" gear by heavy chains (in magenta). The gear would then rotate the center shaft. For maximum efficiency, all the forces on the treadles and pump-handles would need to be synchronous.*

In the front of the engine there is only one bow-tie gear (with chains). Its function is to translate the up and down motion of the treadles into a rotation of the center shaft. In the back of the engine, under the pump housing, there are two bow-tie gears. One of them is for the treadles just like in the front. The other translates the rotation of the center shaft to an up and down motion that drives two piston rods.

The piston rods, connected to the bow-tie gear by the chains, then drive the pistons up and down inside the two dark gray cylinders. Also shown here are the relative positions of the air vessel (blue) and the connection to the nozzle.

*Newsham's competitors criticized this need for coordination, saying that only a trained team would be able to operate it successfully. Newsham argued that the men on the treadles would not tire as quickly as those on the pump handles. In New York the volunteers were trained.